FRP Fencing Manufacturer

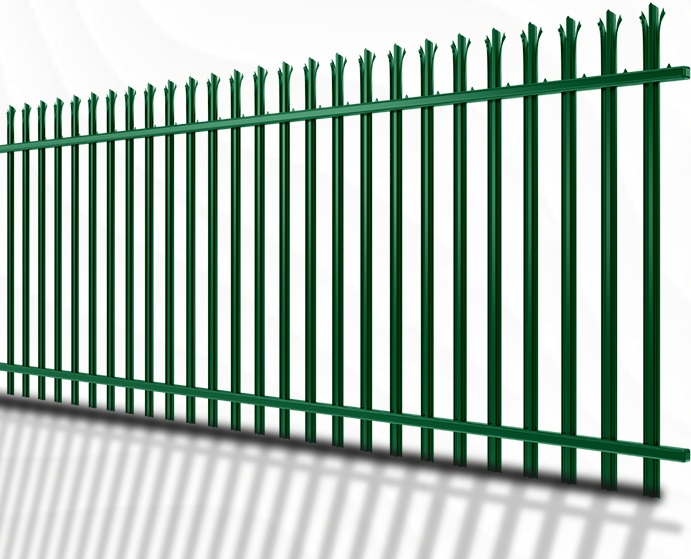

At Aangi Advance Composite, we specialize in manufacturing high-performance FRP (Fiber Reinforced Polymer) Fencing systems designed to meet the evolving needs of modern infrastructure. As part of our commitment to continuous innovation, we’ve developed advanced FRP fencing solutions that offer superior protection and security around electrical installations, industrial machinery, and sensitive zones requiring non-magnetic, thermally stable, and electrically non-conductive barriers.

Our FRP fencing is engineered to deliver virtually maintenance-free performance in harsh industrial environments where traditional materials like wood, steel, or concrete often degrade or fail. With unmatched durability, corrosion resistance, and lightweight construction, our fencing systems are setting new standards in safety and reliability.

Applications of FRP Fencing

FRP fencing is increasingly being adopted across a wide range of sectors due to its unique properties. Common applications include:

- Electrical Substations & Power Plants: Non-conductive fencing ensures safety around high-voltage equipment.

- Industrial Facilities: Ideal for corrosive environments like chemical plants and refineries.

- Railways & Transportation Hubs: Lightweight and durable fencing for secure perimeters.

- Commercial & Residential Complexes: Aesthetic and long-lasting alternative to traditional fencing.

- Coastal & Marine Areas: Excellent resistance to saltwater and humidity.

- Laboratories & Research Centers: Non-magnetic and non-sparking properties make it ideal for sensitive environments.

Why FRP Fencing Demand Is Rising ?

The demand for FRP fencing is growing rapidly due to several key factors:

- Corrosion Resistance: Unlike metal, FRP doesn’t rust, making it ideal for outdoor and industrial use.

- Electrical Insulation: Essential for safety in power and utility sectors.

- Low Maintenance: No painting, no rust treatment—just long-term reliability.

- Lightweight & Easy Installation: Reduces labor costs and installation time.

- Sustainability: Longer lifespan means fewer replacements and less environmental impact.

- Regulatory Compliance: Increasing safety standards are driving adoption in critical infrastructure.