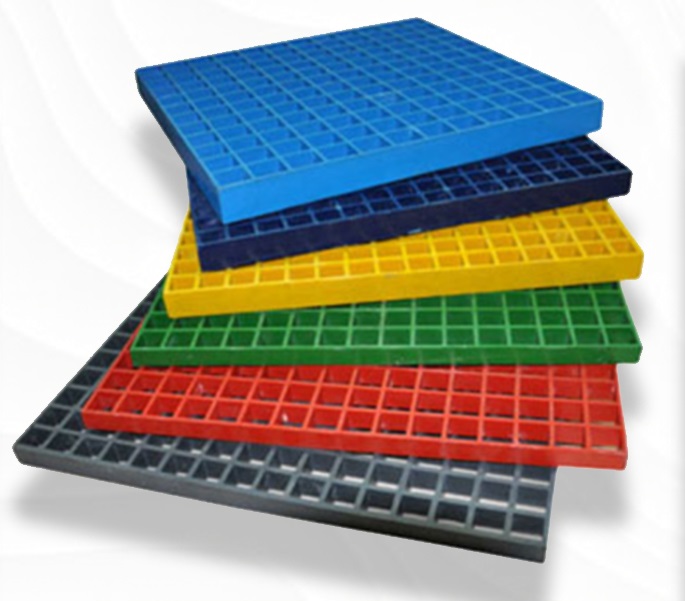

FRP Gratings Manufacturer

This surface allows the separation between two levels it prevent dripping or smoke to pass and assure complete safety for below pedestrian transit. The right solution for applications where forklift and trolley transit is frequent.